Fixed Frequency Screw Compressor with Air Tank And Air Dryer

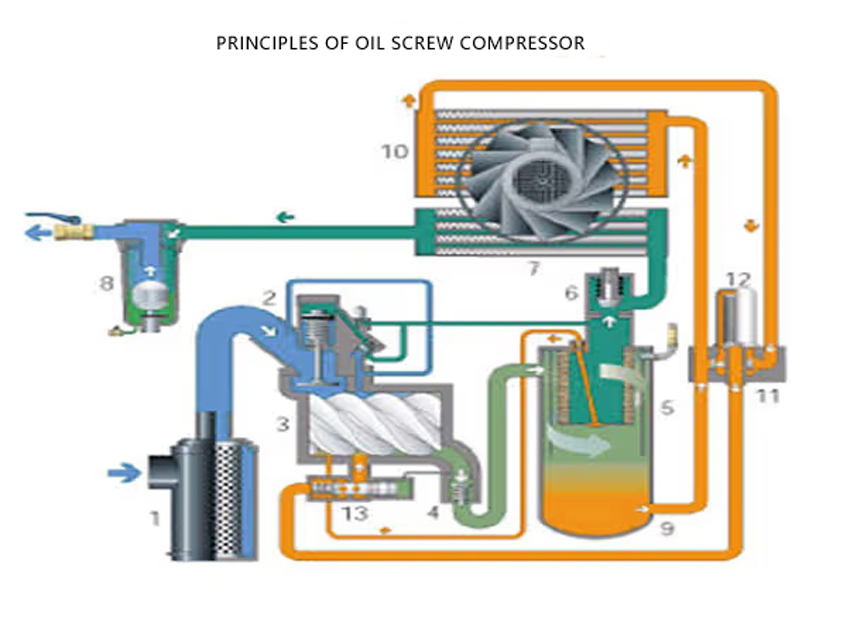

A. Air path:

The air passes through 1 air filter, via 2 control valves, enters 3 compression chambers. then compressed by the screw to produce high-temperature and high-pressure oily air, which enters 5 oil-air separator for separation (centrifugal separation). the high-temperature gas passes 6 control valves to reach 7 cooling fans cooling, and then discharged through 8 the control valve.

B. Oil path:

The lubricating oil in the oil-air separator passes through the 9 oil pipe and the 11 oil control valve, and reaches the 10 cooling fan for cooling. After cooling, the lubricating oil is filtered in the 12 oil filter to filter debris and dust generated during the operation of the air compressor. after then through the 13 oil control valve, enter 3 the compression chamber to lubricate the screw. While the screw is compressing the air, the lubricating oil is brought into the 5 oil-air separator to complete the oil circulation.

FULL SET CONNECTION METHOD OF OUR FIXED FREQUENCY SCREW COMPRESSOR

MAIN FEATURES OF OUR FIXED FREQUENCY SCREW COMPRESSOR:

1. High reliability: The screw air compressor has few parts and wearing parts, so it operates reliably and has a long service life.

2. Convenient operation and maintenance: the operator does not need to undergo long-term professional training, and can realize unattended operation. The operation is relatively simple, and the air can be supplied according to the required displacement.

3. Good power balance: the screw air compressor has no unbalanced inertial force, the machine can work smoothly at high speed, and can realize non-foundational operation.

4. Strong adaptability: The screw air compressor has the characteristics of forced air delivery, the exhaust volume is almost not affected by the exhaust pressure, operation is stable, vibration is small, exhaust is stable, and can maintain high efficiency in a wide range .

5. Multi-phase mixed transmission: there is actually a gap between the rotor tooth surfaces of the screw air compressor, so it can withstand the impact of liquid, and can pressurize liquid-containing air, dust-containing air, and easily polymerized air.

6. The unit exhaust volume is small, which saves the occupied area.

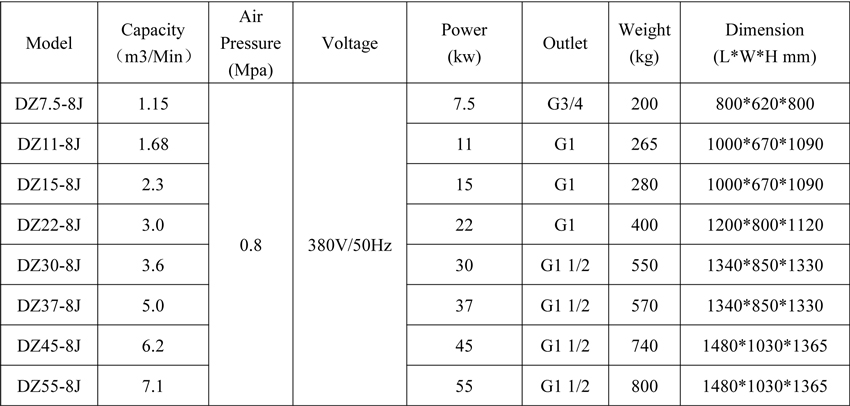

PARAMETERS OF OUR FIXED FREQUENCY SCREW COMPRESSOR:

FREQUENTLY ASKED QUESTIONS FOR OUR FIXED FREQUENCY SCREW COMPRESSOR:

1. How to get the right type screw compressor for me?

To get the fast and best answer,we need to confirm:

A. How many cbm per hour of the capacity you need?

B. How much output air pressure you need?.

C. Do you have the budget to purchase of our screw compressor?

2. How long it will be to get the screw compressor after paid?

It is 10-30 working days depends on situation. Holidays or peak sales season may be slow.

3. Do you have the warranty for your machine?

Yes,we have warranty for our machine for 1 year. You can also buy an additional warranty period.

During the warranty period of our color sorter machine,we will send the parts to our user for total free.If out of warranty,we will charge a reasonable fee for the parts.

4. Do I need to buy spare parts?

It depends.we can sell you some and send together with the machine.

5. It is easy to use your screw compressor?

Yes. Usually,you can just start our compressor after installation.

6. Does your machine have English language?

Yes,our compressor is equipped with English language.

7. Does your compressor have good quality?

Yes,our compressor use high standard of motor and screw,which ensures stability and long life span.also we offer 4 grade filters to make the final air more cleaner, reducing damage to the equipment.